Painting Simulator

Painting simulator is one of the most essential devices used in painting training. Painting simulator using virtual reality technology is one of the most important tools used to facilitate spray painting, powder coating and abrasive blasting training.

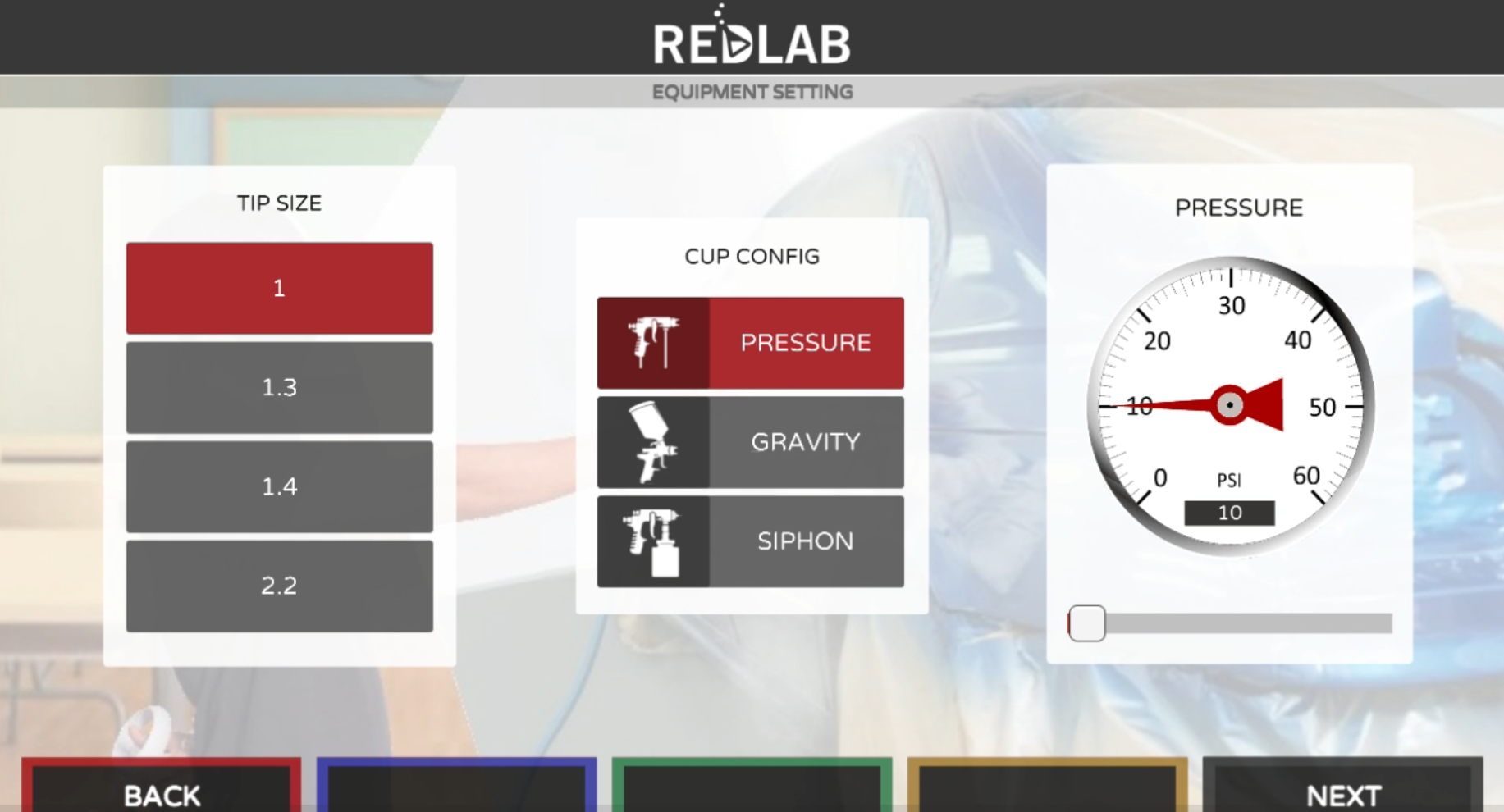

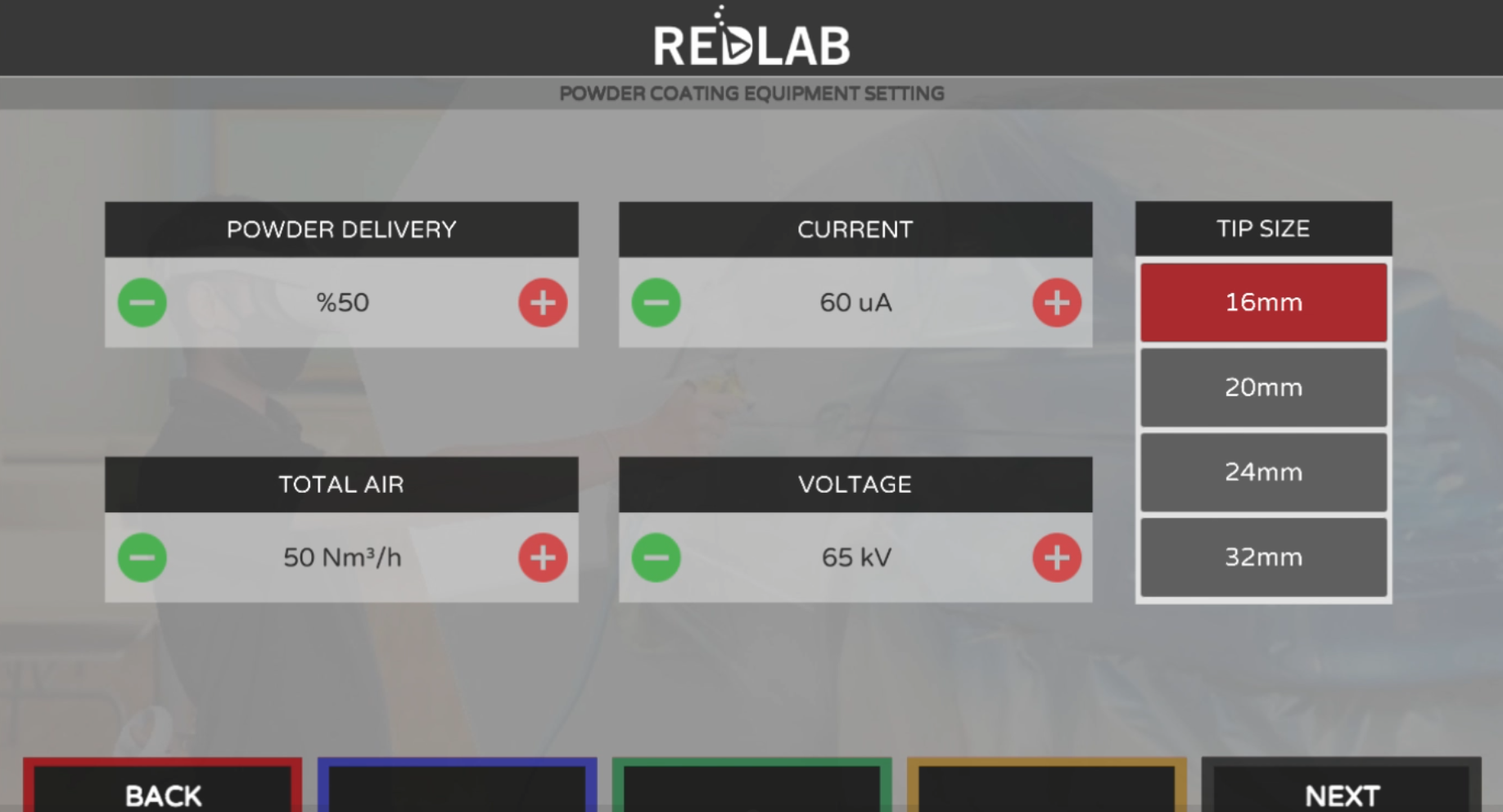

The use of painting simulator technology in painter, blaster and powder coater training applications instead of traditional methods improves learning and reduces material waste; paint technique, material, color, working area, pressure, tip size and other configurations may all be altered quickly.

REDSPRAY PAINTING SIMULATOR RED-PS200

VR painting simulation system equipment:

- Painting machine, - Spray gun - Powder coating gun - Blasting gun - Virtual reality supported helmet.

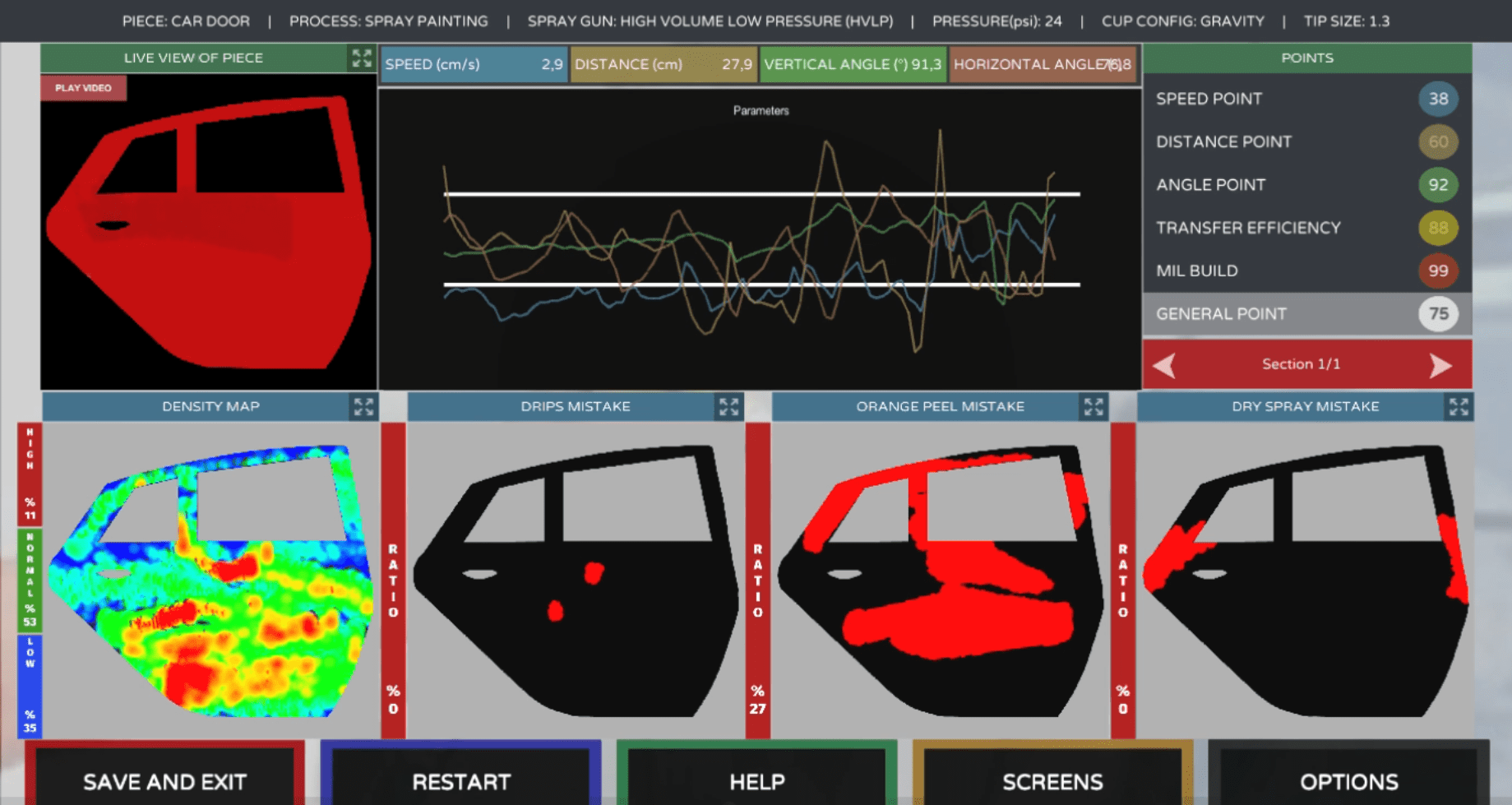

Analyzed Parameters:

- Speed, - Angle, - Distance, - Transfer efficiency, - Mil build.

Analyzed painting errors:

- Drips, - Orange peel, - Dry spray, - Insufficient penetration, - Outgassing.

Analysis of Painting

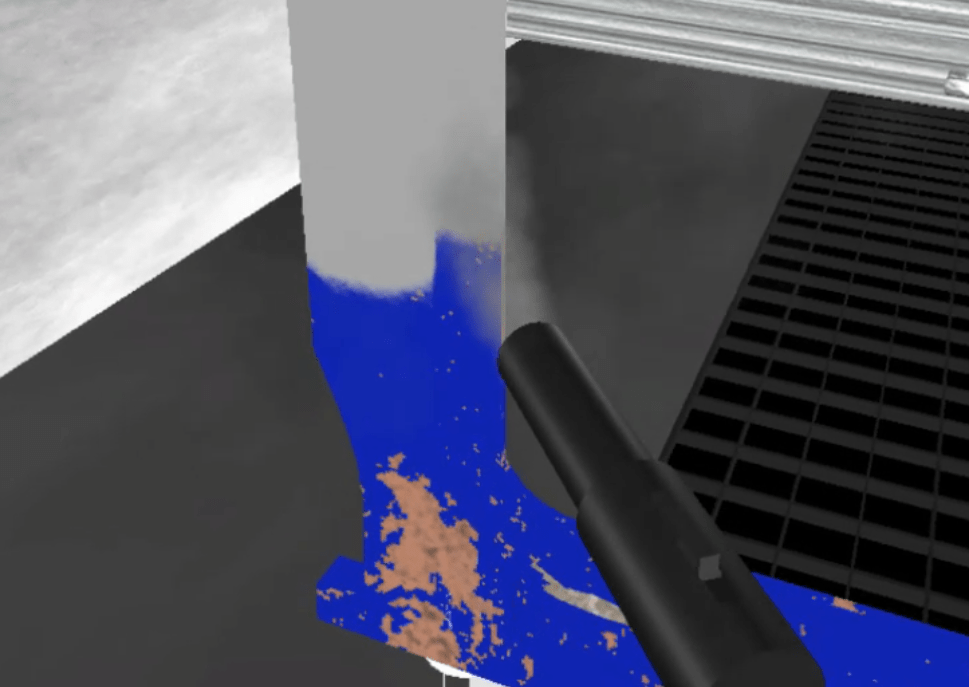

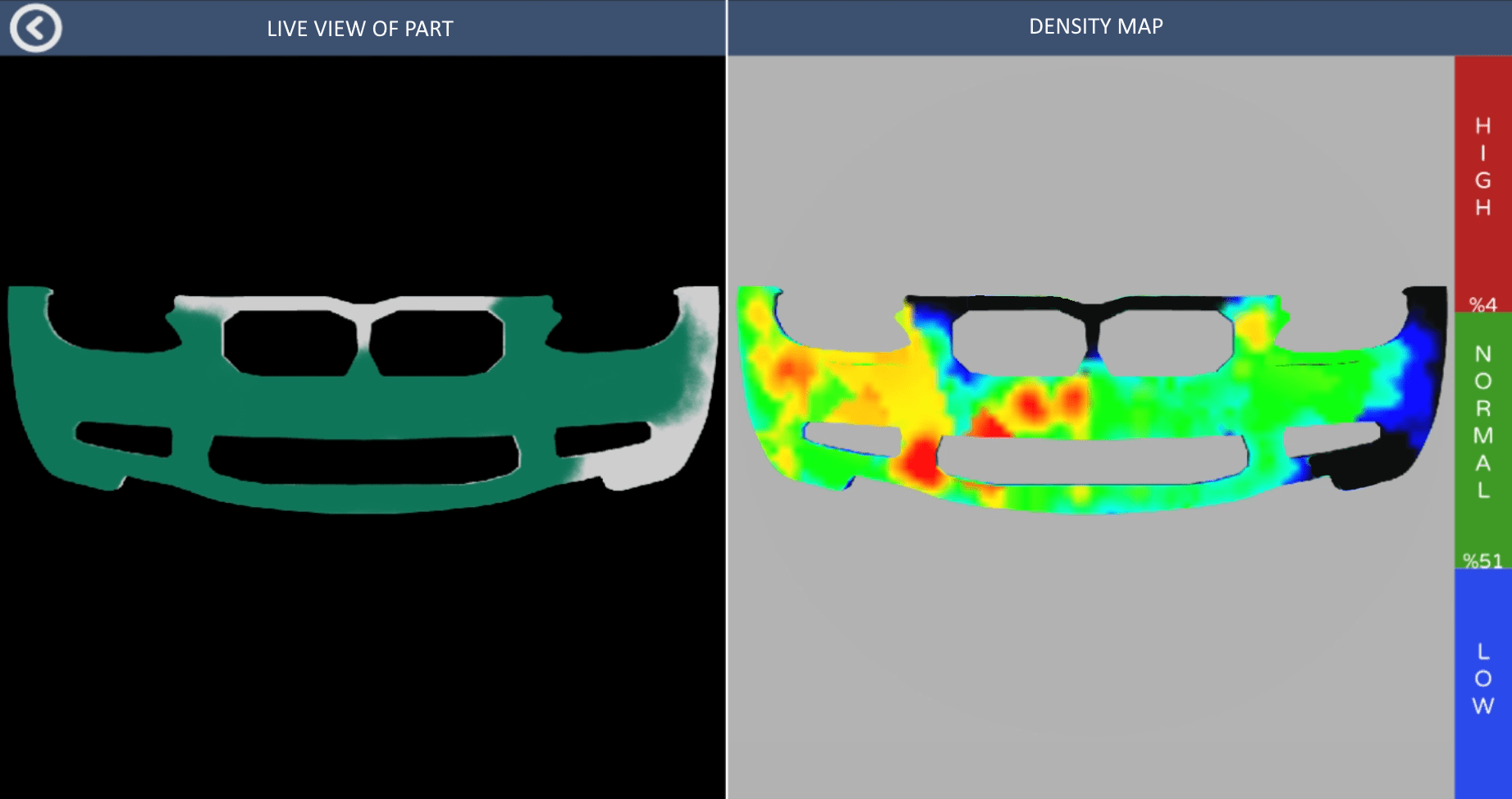

There is a analysis screen where the user can examine the part he/she is painting. On this screen, the paint on the part is mapped with blue, red and green colors. By mapping the thickness of the paint in that location according to the progress vector, the entire part can be visually analyzed. Instant analysis of painting parameters and mistakes is provided. On the data screen, all data may be displayed graphically. Analysis can be used to evaluate the painting. It is possible to capture the painting report as well as the painting video. All data can be recorded on a single platform to track real-time assessment of students. All analysis data can be saved as PDF.

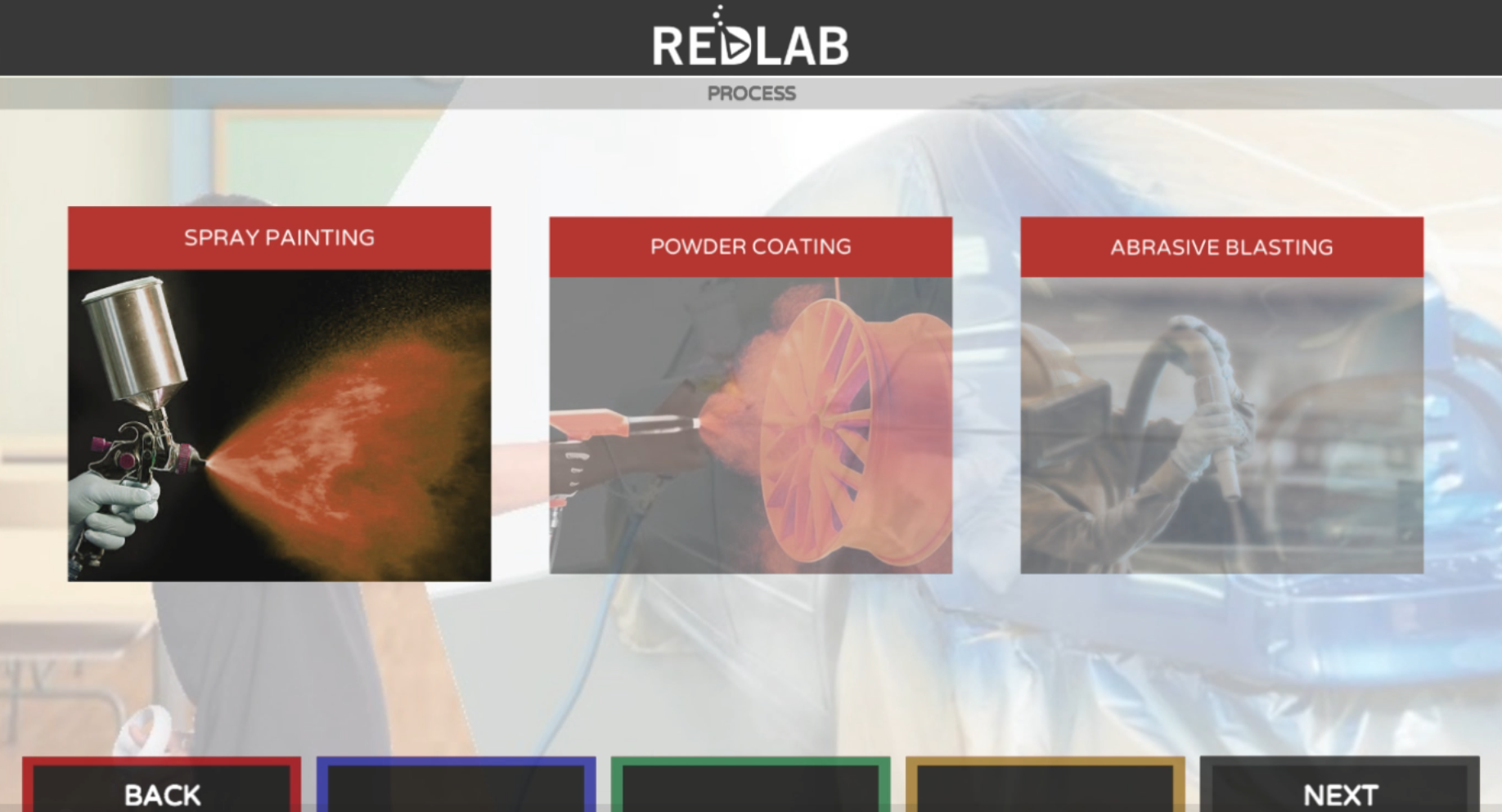

Available Processes

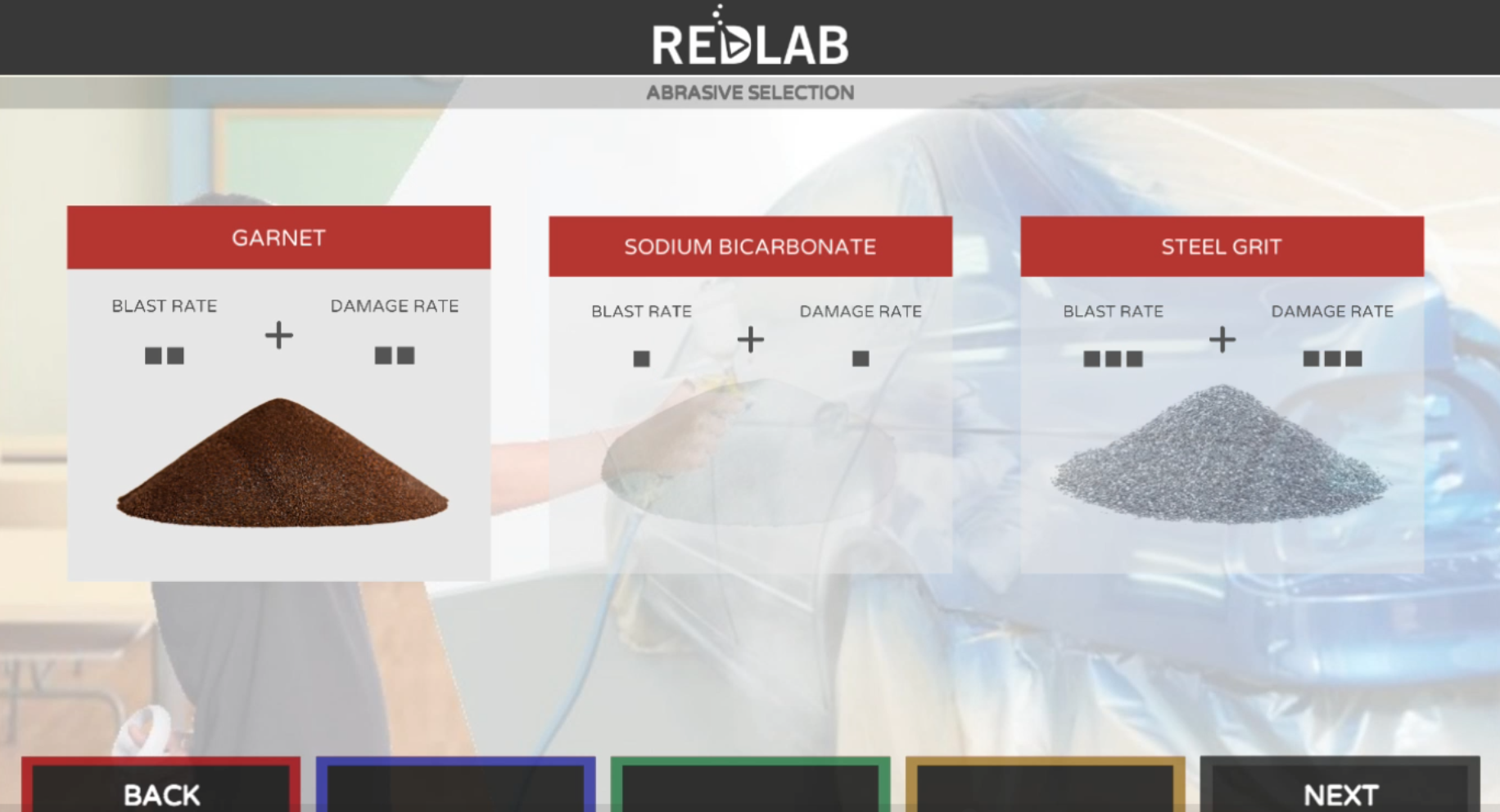

The simulator includes coating and abrasive blasting modules as well as the painting module.

- HVLP with 3 types of cup configurations (pressure, gravity, siphon). - Airless - Air Assested Airless - Powder Coating - Abrasive Blasting

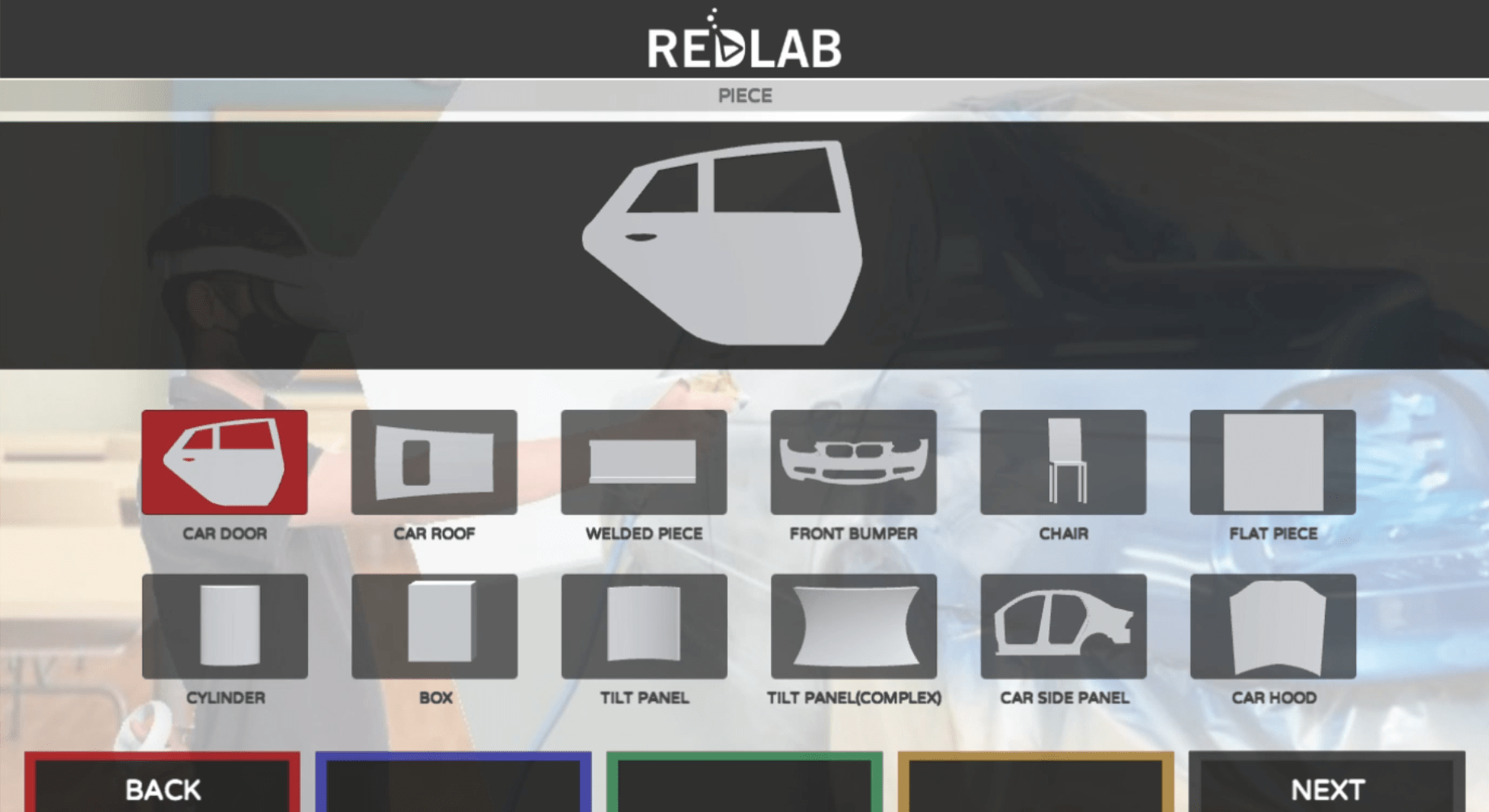

Part Selection

At least 12 work pieces can be worked with (Vehicle door, Vehicle roof, Welded part, Front bumper, Chair, Flat part, Cylinder, Box, Curved panel, Curved panel (Complex), Vehicle side panel, Vehicle hood).

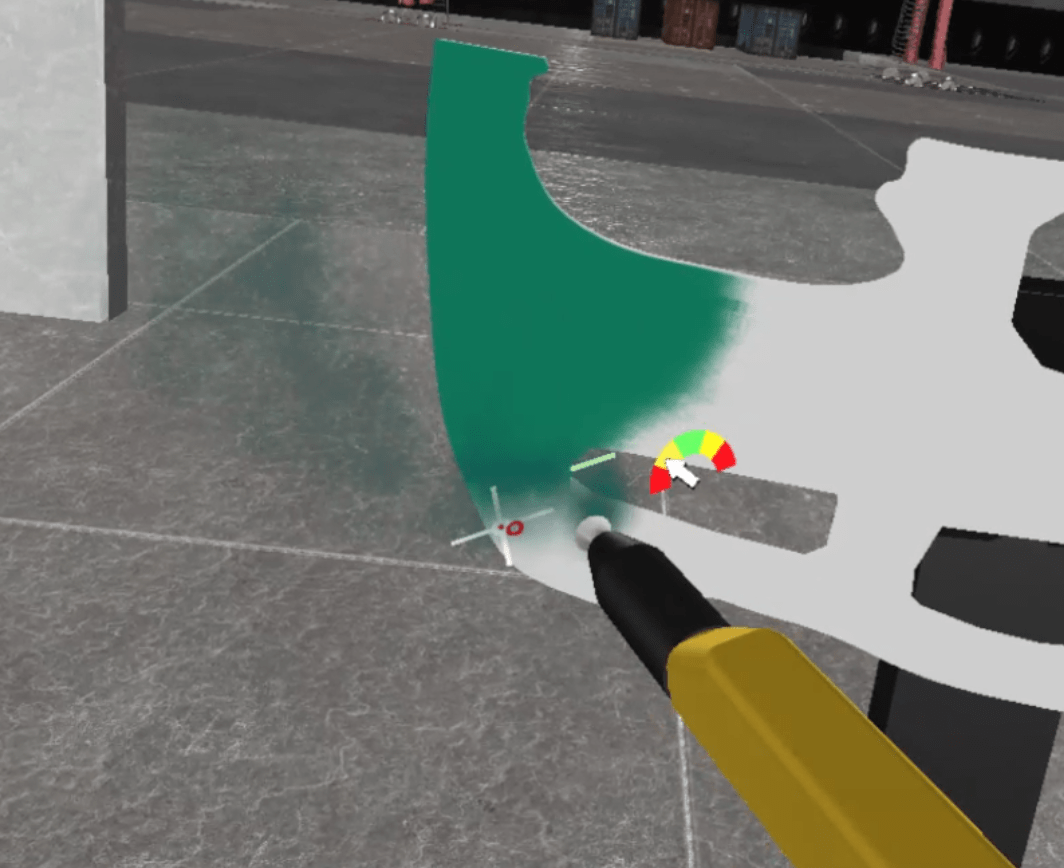

Assistance (Visual Hint)

Visual hints can be observed before or during the painting process, assisting the operator in painting with more precision.

- Speed assistance can be used to ensure that progress is maintained at optimum levels. - By looking at the angle assistance, you can keep the travel and work angle at their best. - By examining at the distance assistance, you can keep the distance at its best.

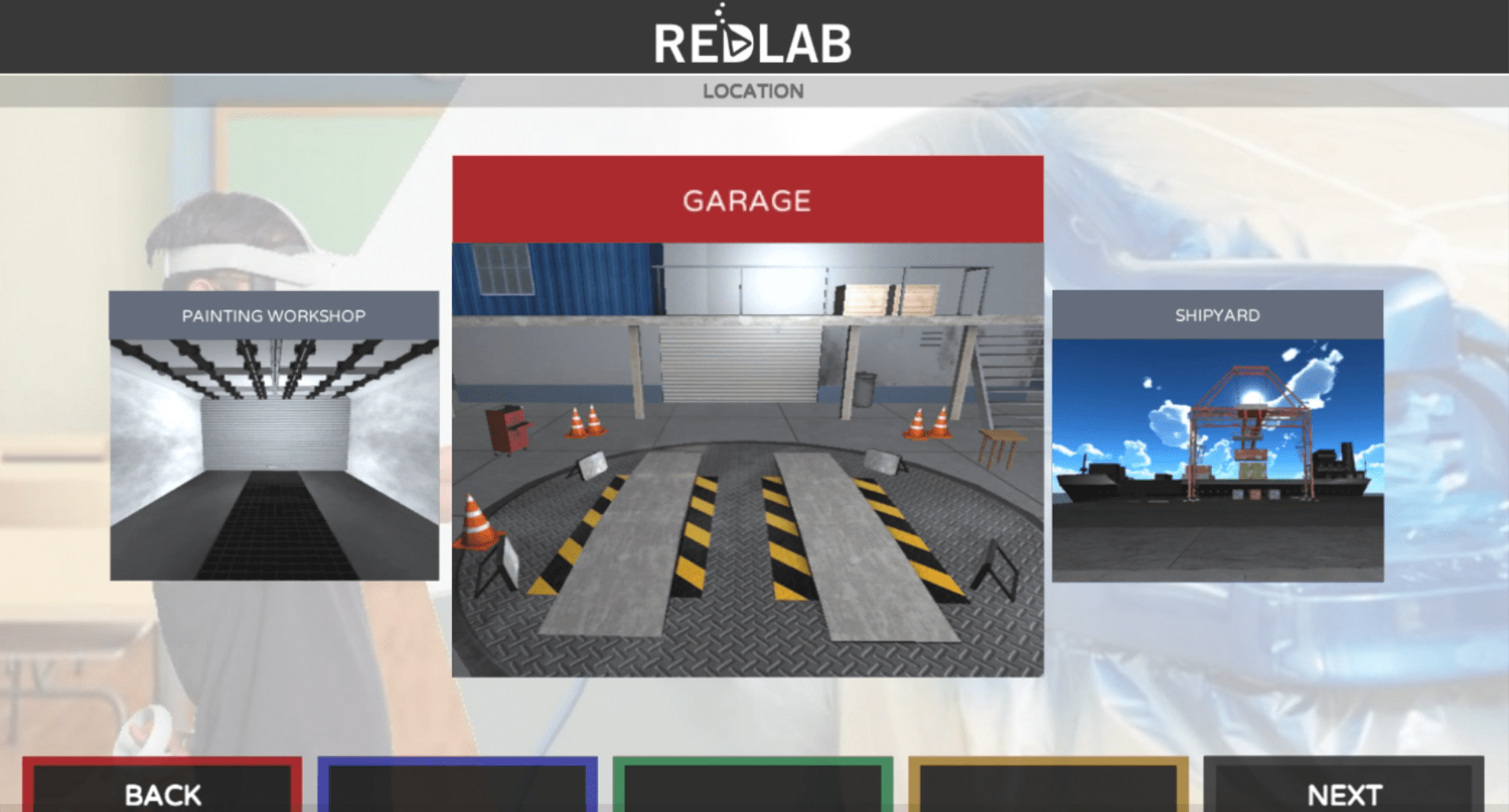

Area Selection

Painting in different areas can be experienced by changing the environment to be painted. It is possible to move in the all direction within the selected virtual environment.

- Car garage, shipyard, paint shop, military hangar environments can be selected.

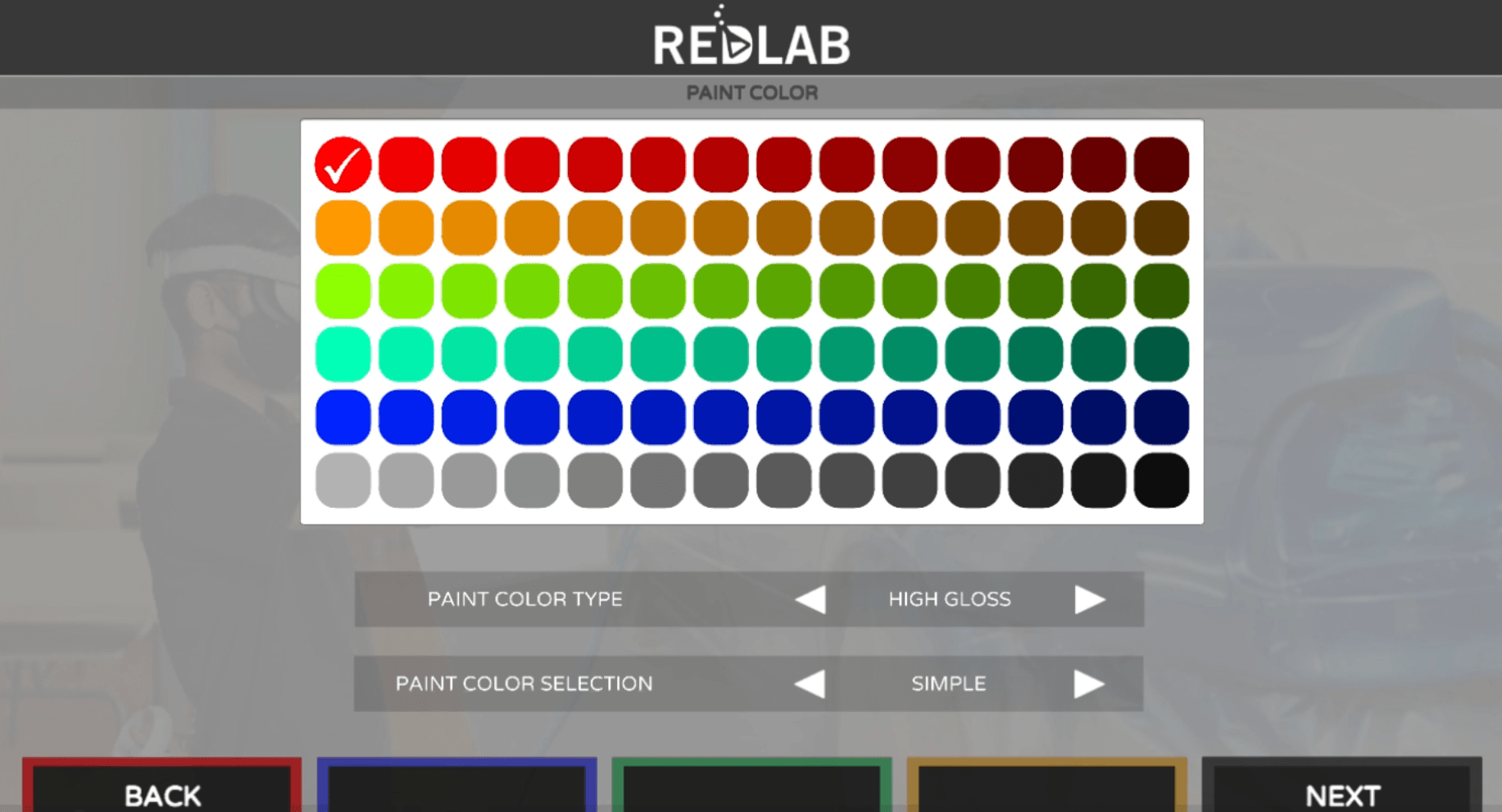

Painting Parameters Selection

- Pressure, spray angle, spray direction, powder delivery, volt, ampere, total air etc. can be adjusted. - Tip types can be selected. - Cup configurations can be adjusted. - Colour can be selected.

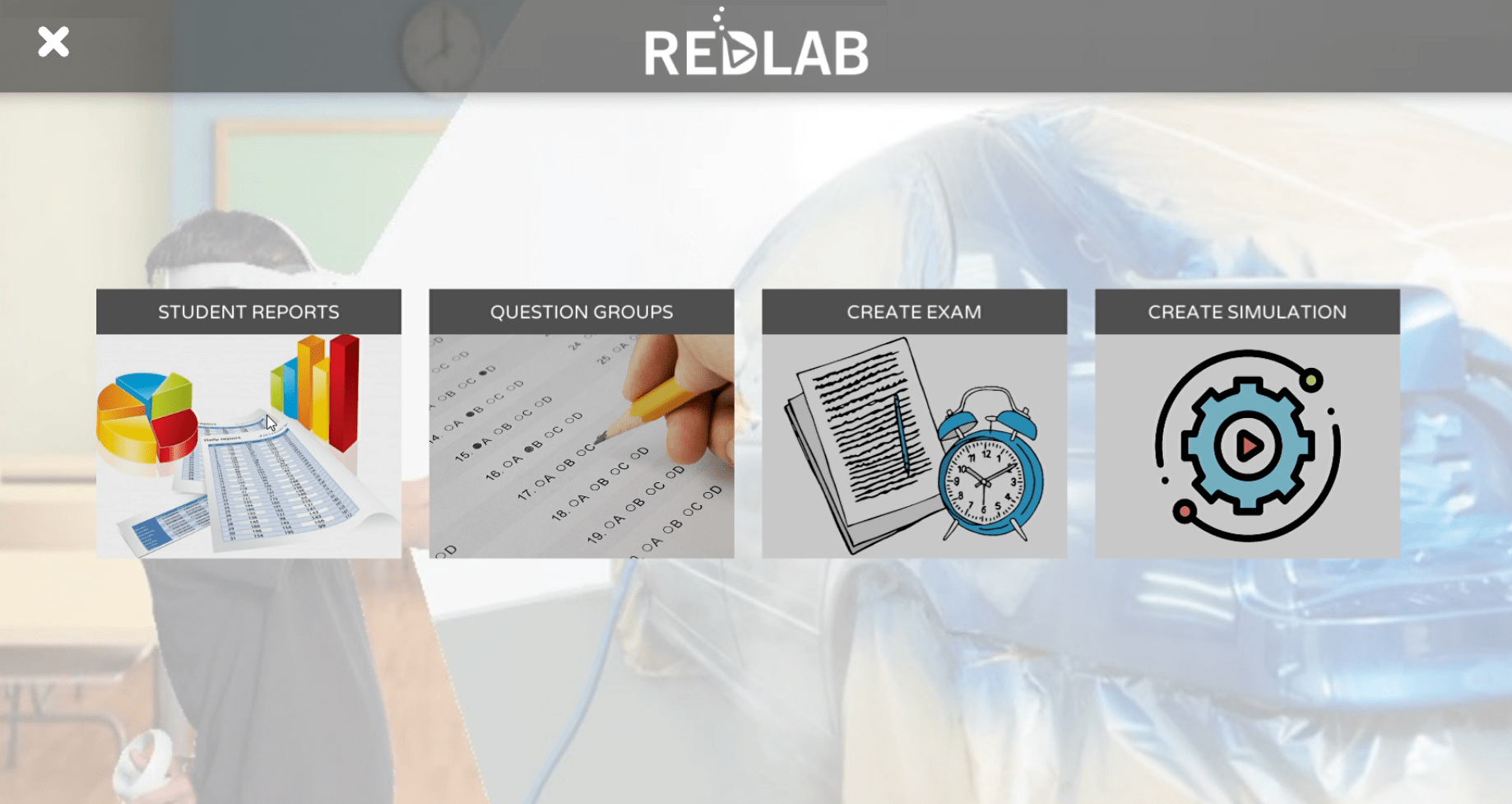

Learning Management System (LMS)

- All data and evaluation score of the painting performed by users can be accessed. - Video footage of users recorded during the painting can be viewed. - Multiple-choice exams can be created to evaluate users. - Exam result data can be examined. - User data for up to 20 users can be compared graphically. - With the Teacher System that can be installed on an external computer, the device can be connected remotely and the simulation can be started from the Teacher system.

Worldwide Shipping

REDSPRAY painting simulators are shipped to all countries in a protected wooden box by air, land and sea. Carefully delivered anywhere in the world. Shipping arrangement methods: DAP, EXW, FOB, CIF, CFR.

Painting Simulator Technical Specifications

1- The paint simulator has VR feature. 2- It has fast installation and user-friendly interface with touch screen and can be activated with a single button. 3- The simulator can work in any environment where there is an electrical connection (classroom, workshop, etc.). 4- It has HDMI output for connection to TV or projector. 5- It works with 110 - 230 V 50 - 60 Hz. 6- Work can be done on the following work pieces: Flat, Curved, Complex parts. 7- The simulation has a high realism. 8- At least 12 work pieces can be worked with (Vehicle door, Vehicle roof, Welded part, Front bumper, Chair, Flat part, Cylinder, Box, Curved panel, Curved panel (Complex), Vehicle side panel, Vehicle hood). 9- The color scale includes commercially available colors and is available in gloss, semi-gloss and matt. 10- Visual aid activation panel is available. 11- Real-time scoring is available. 12- The following defects can be displayed: Dripping, Orange peel defect, Dry spray 13- The work can then be seen again in 3D and parameters such as paint angle and distance are shown in different colors and the details of the work can be examined. 14- The work done by the students can be followed step by step and reported. 15- Movement can be tracked (angle, distance, speed). 16- Errors in painting can be mapped and the mistakes made can be clearly seen. 17- There are screens that adjustments/ pre-settings are done on the interface where the techniques and materials to be used in painting such as; name entry screen, data saving screen to USB memory, application update screen, paint technique selection screen, paint material selection screen, paint color selection screen, paint gun and specification screen, area selection screen, equipment settings (part offsets, air pressure, tip size and other configurations) screens. 18- All entered data is saved in the local database of the simulator using the MYSQL database system by using the middle layer to be developed with the Php software language. 19- The simulator includes abrasive blasting and coating modules as well as the painting module. 20- The simulator have Faraday mode feature. 21- Spray angle can be adjusted. 22- For evaluation following parameters are used: the angles that the student makes while holding the paint gun in virtual reality, the distance of the gun to the material, the progress speed the parameter values selected before starting painting. 23- There is a mapping screen where the user can examine the part he/she is painting. On this screen, the paint on the part is mapped with blue, red and green colors. By mapping the thickness of the paint in that location according to the progress vector, the entire part can be visually analyzed. 24- All data can be recorded on a single platform to track real-time assessment of students. 25- Manufacturer can be reached out for technical support requirements. 26- User data for up to 20 users can be compared graphically. 27- Spray paint gun, Powder coating gun, sandblasting gun are similar in structure and weight to the real ones. 28- All analysis data can be saved as PDF. 29- With the Teacher System that can be installed on an external computer, the device can be connected remotely and the simulation can be started from the Teacher system.