Welding Simulator

Virtual reality and augmented reality technology can be used to facilitate welding training in a simulation environment.

The use of welding simulator technology in welding training applications instead of traditional methods reduces material waste and improves workplace safety; joint methods, welding positions, materials, material thicknesses, and welding type may all be altered quickly.

REDWELD WELDING SIMULATOR RED-WS100

VR / AR welding simulation system equipment:

- Welding machine, - Welding desk, - Stand system where the heights and positions of parts can be adjusted, - Under-gas and tig torches in original weight and structure, - Custom design welding pliers, - Virtual reality / augmented reality supported welding mask.

Analyzed Parameters:

- Feed rate, - Advance angle, - Operating angle, - Arc length distance, - Position, - Distance between contact nozzle and workpiece.

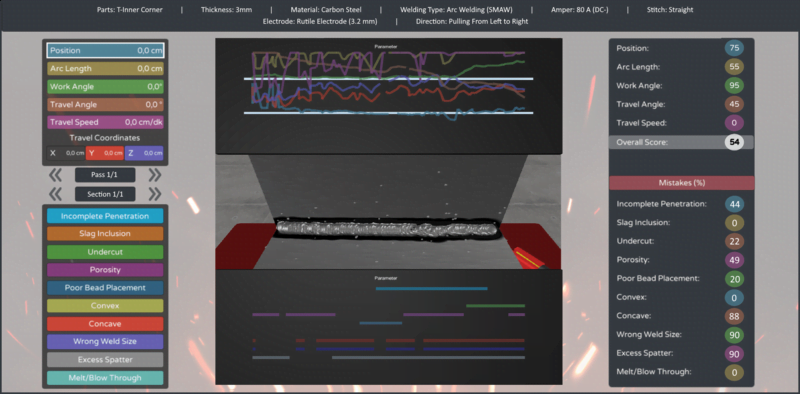

Analyzed welding errors:

- Insufficient penetration, - Slag containment, - Combustion groove, - Porosity, - Poor drop placement, - Excessive outer / internal bending, - Incorrect welding size, - Oversplating, - Melting / inflating.

REDWELD COMPACT WELDING SIMULATOR RED-WS200

VR / AR welding simulation system equipment:

- Welding machine, - Under-gas and tig torches in original weight and structure, - Custom design welding pliers, - Virtual reality / augmented reality supported welding mask.

Advantages:

- Small size compact design, - Less freight cost, - Allows welding without stand and real parts, - Contains all the technical features of RED-WS100.

Analysis Screen

- Instant analysis of welding parameters and mistakes is provided. - On the data screen, all data may be displayed graphically. - It is possible to inspect a live welding seam. - Welding failures are displayed along with their location on the material. - Analysis can be used to evaluate the welding. - Separate analyses can be performed on welded sections and passes. - It is possible to capture the welding report as well as the welding video. - Simulations of leaping slag and electrode melting are possible. - It is possible to remove the welding shell and clean the welding seam.

Part Selection Screen

- Welding part positions (ceiling, perpendicular, horizontal, cornice) can be changed. - Parts for welding and connecting positions can be chosen. - The thickness of the items to be welded might range from 3 to 10 millimetres. - Carbon steel, stainless steel, and aluminium are all options for part materials.

Help (Visual Hint) Screen

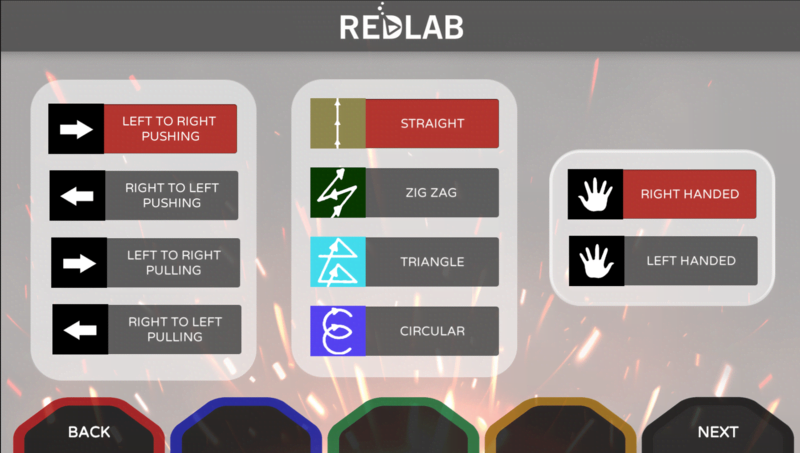

Visual hints can be observed before or during the welding process, assisting the operator in welding with more precision.

- Use the guideline assistance to see where the welding should be done. - Speed assistance can be used to ensure that progress is maintained at optimum levels. - By looking at the angle assistance, you can keep the advance and operating angle at their best. - By examining at the distance assistance, you can keep the arc length at its best.

Area Selection Screen

Welding in different areas can be experienced by changing the environment to be welded. It is possible to move in the all direction within the selected virtual environment.

- The construction area (open environment) can be selected. - Welding workshop environment (indoor environment) can be selected. - Maintenance facility environment (open environment) can be selected.

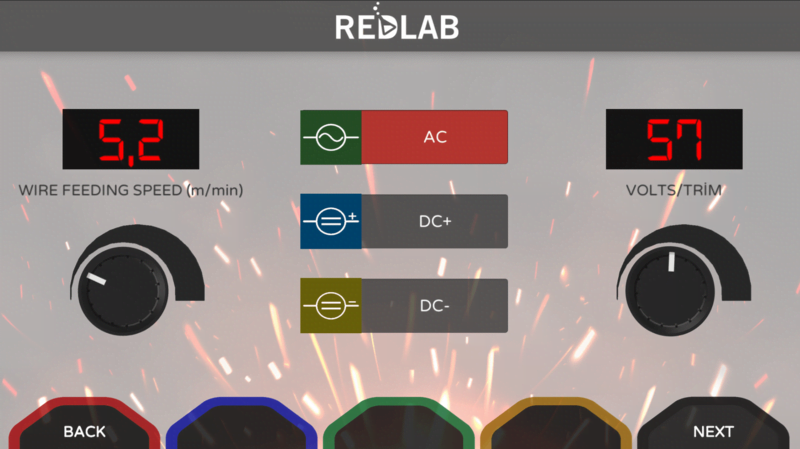

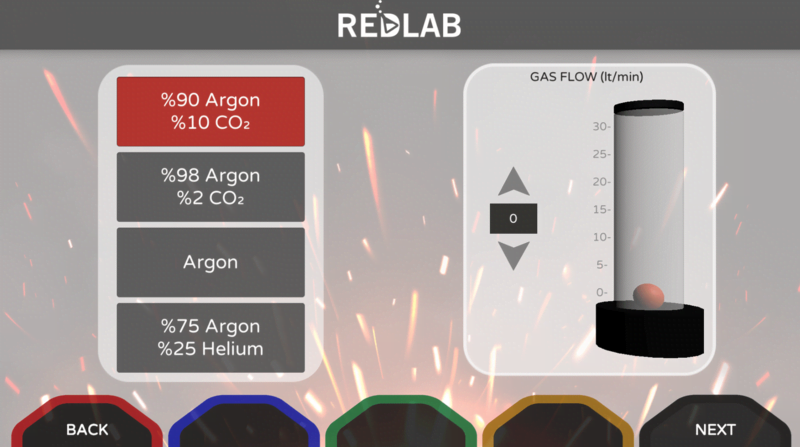

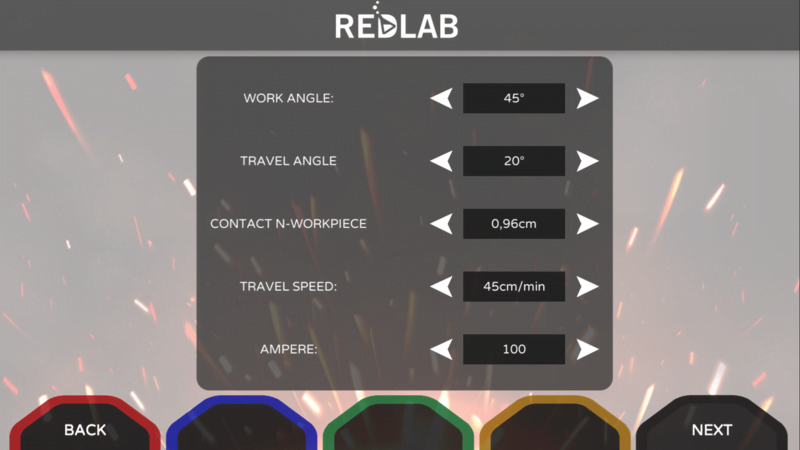

Welding Parameters Input Screen

- Current, volt, wire riding speed values can be adjusted. - AC, DC+, DC-polarization can be selected. - Gas mixture and gas flow can be adjusted. - Electrode material and diameter can be selected. - Welding seam direction and seaming technique can be selected.

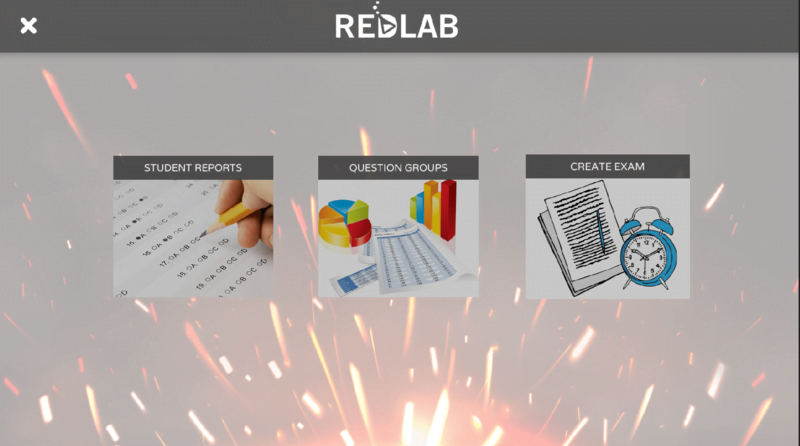

User Evaluation Screen

- All data of the welding performed by users can be accessed. - Video footage of users recorded during the welding can be viewed. - Multiple-choice exams can be created to evaluate users. - Exam result data can be examined.

Welding Simulator Technical Specifications

1- In the Welding Simulation Training Set based on the virtual reality (VR) system; It consists of welding machine, welding types and position plates, welding mask, welding table. 2- It has original gas metal arc and tig torches and specially designed electrode arc welding pliers (SMAW - Electric arc welding). 3- Welds according to at least 6 welding positions (V-notch 6” (150 mm) Pipe, V-notch Plates, T-Inner Corner, T-Inner Corner 6” (150 mm) notch pipe with plate and plate overlay) and straight stitching. 4- Working angle, feed rate and angle, feed coordinates, weld seam guide lines and arc length distance can be measured accurately and data (numbers and graphics) can be viewed instantly. 5- The thickness of the workpiece can be selected between 3 and 10 mm and material selection (Carbon Steel, Stainless Steel and Aluminum) can be made. 6- According to welding types, welding torches, gas metal arc and tig torches have original weight and structure (with their real equivalents), different wire thicknesses can be selected with the electrode selection. 7- Device; It can perform electric arc welding (SMAW), gas submerged arc welding (GMAW-GTAW), cored wire arc welding (FCAW), TIG welding. 8- CO2, ARGON-CO2 mixture and ARGON options are available as shielding gas. 9- Real-time feedback is provided on the welding technique applied using visual cues. 10- Supervision and control of the welding applications and ethernet or wireless access to all data with the teacher's computer. 11- Amperes and volts can be adjusted according to welding types and positions. 12- In addition to the exercises performed by the users and the analysis results of these exercises, it is possible to store the video of the exercise on the simulator device. 13- Scoring can be made by considering how well the student welds according to the welding technique determined by the teacher. 14- Student studies or possible welding errors can be analyzed by the system, reported and transferred to the teacher's computer with the simulator screen. 15- The welding technique applied by the student is shown with a graph containing lines of different colors, and this graph consists of lines belonging to different parameters. 16- There is a scoring system for the evaluation of the user. With the help of this system, users can be tested, and a multiple-choice exam can be applied to users with the teacher software. 17- Position of welded joint, distance between contact nozzle and workpiece, working angle, feed angle, feed rate, reaching target, weld porosity, electrode; It simulates the situations where it melts and can be replaced with a new one while using, and splashing slag situations are simulated. 18- Overlay welding can be performed from normal and single pass up to 4 passes in the welding simulator. 19- It allows manual and automatic trigger options while simulating gas metal, cored wire and tig welds with the simulator. 20- There are flat, zig zag, triangular crescent and circular weld seam options. 21- With its right-to-left and left-to-right welding feature, the welding apparatus and the software are also suitable for right-handed and left-handed users. 22- There is an adjustable work stand in different positions to place the welding parts. 23- The welding mask is adjustable with full head protection and there is sufficient inner depth between the screen in the mask and the forehead so that students with glasses can also use it. The apparatus has VR technology. 24- In electrode and cored wire welding, there is a shell cleaning feature for observing before and after the removal of the welding shell. 25- The welding simulator has licensed teacher software. The software can be updated in accordance with the technological requirement. 26- Since the system is a computer simulation, there is a 21” monitor and other equipment, internal USB, ethernet, HDMI cable in order to watch the images in the system.